Understanding Diecasting: The Course of and Its Applications

Understanding Diecasting: The Course of and Its Applications

Blog Article

Diecasting can be a flexible and widely used manufacturing process which involves the injection of molten metal into a mold cavity at intense pressure. This method is highly efficient to create large quantities of complicated metal parts, that have excellent accuracy in dimensional measurement and a smooth surface finish. Materials, processes, as well as the various applications for diecasting, are crucial to many sectors, which makes it an integral part of manufacturing today. The article examines the basic principles of diecasting, its benefits as well as the many applications it has for the business.

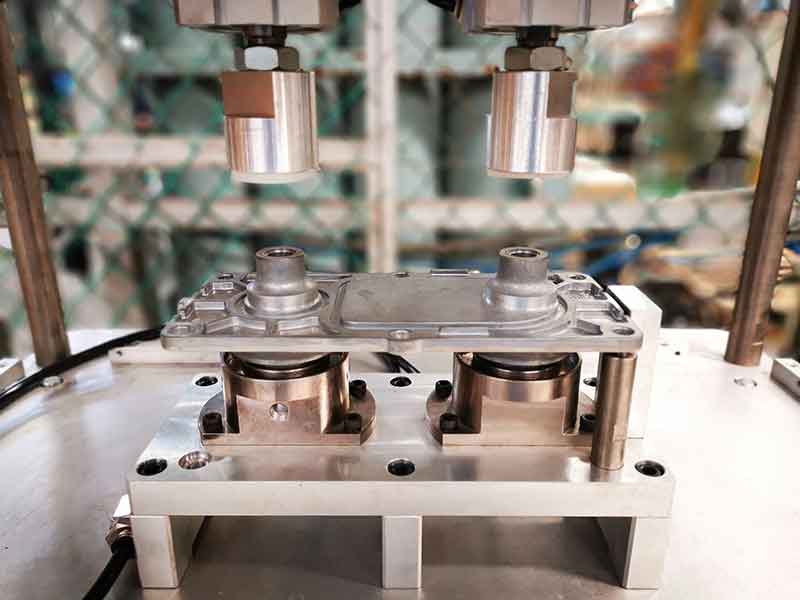

The core of diecasting is the mold, known as a"die," which is carefully designed and constructed from solid steel, which is hardened to resist the harsh conditions that are encountered during this casting. The shape of the die is essential, because it needs to be able to handle the molten metal's flow and hardening while maintaining tight tolerances to ensure high-quality. During the diecasting process that involves the use of metals, such as aluminum, zinc as well as copper are heated up until they melt. The molten material is forced into the die cavity with high pressure, and fills every crevice in the mold. The rapid cooling and formation of solidified metal results in components that have high dimensional precision and smooth surface finish, often eliminating the need for additional processing or finishing.

One of the main advantages of diecasting is the efficacy in mass production. When dies are manufactured and shaped, they are able to create thousands of identical parts that are identical with little variation. This high level of repeatability is essential for industries which require huge quantities of uniform parts. Additionally, diecasting is known for its high efficiency of materials. It produces little waste, as excess metal is reused in subsequent casting cycles. This reduces not just cost of materials but also helps to promote sustainable manufacturing practices by minimizing the use of resources and reducing waste. A combination of production speed, precision of the material, and high efficiency make diecasting an attractive option in the quest to maximize their production processes.

Diecasting has numerous advantages with regard to mechanical properties. Diecast components typically exhibit excellent strength and durability due to the fine-grain structure created during the fast cooling of molten metal. These components are ideal for applications that demand quality and performance. In addition, the process allows to integrate thin walls and complex features with no compromise to their structural strength. This is especially beneficial when it comes to aerospace and automotive industries where weight reduction while maintaining strength is critical. It is possible to make light, but strong parts aids in improving fuel efficiency and efficiency in aircrafts and vehicles. To get more details kindly check out Senadiecasting

The versatility of diecasting extends to its wide range of uses across various industries. For instance, in the automobile industry Diecast components play an integral role to the construction of engines, transmissions, and structural elements, contributing to smaller, lighter vehicles that are more efficient in fuel consumption. In the electronic sector the use of diecasting can be used to create heat sinks connectors and housings, making sure that the proper thermal management is in place and long-lasting electronic components. Consumer goods also benefits from diecasting, with applications that span from household appliances to power tools and toys. Diecasting's versatility to different metals, as well as its capacity to create parts that have intricate patterns make it suitable for numerous types of applications. Each profiting from the distinctive benefits diecasting brings.

Diecasting is an innovative manufacturing technique that blends accuracy, precision and flexibility. Its ability to produce intricate, high-end parts that possess exceptional mechanical properties makes it essential in all industries. Diecasting's effectiveness for mass production, together with its material and price benefits, underscores its value in today's manufacturing. While industries are continuing to require high-performance and reliable components, diecasting will remain a key technology driving advancement and the creation of innovative products that fulfill the ever-evolving needs of the market. Through its continued advancement and use, diecasting exemplifies the intersection of manufacturing excellence and engineering prowess.